The original manufacturing company’s software would have been here a long time ago.

But in this present era, some developers are able to enhance software performance that is able to adapt to this disruptive era.

Especially in the industrial fields that are moving on manufacturing.

As a quick industry, manufacturing has a very hustle need in all its aspects of the production process.

Manufacturing also requires accurate mahadata, real-time access, and also portable.

So the use of manufacturing production software was mandatory.

The list of manufacturing production software was mandatory to face 4.0

The following are examples of manufacturing manufacturing applications, corporate software production applications, and manufacturing applications software that manufacturing companies are required to have to face the 4.0 era.

What kind of software is required to own a manufacturing company?

- Manufacture Equipment Software

This type of production software gives some ease in the production process.

The function of this production software is to eliminate unnecessary processes, add business value, reduce unplanned stops, prevent production processes, optimize the controls and allocation of production resources, and also increase the full visibility of the quality – based production processes.

Among the features in modern manufactured applications software are these:

- Manufacturing orders: it was easier for manufacturers to give the necessary instructions for manufacturing work, including determining products to be made, amount to, required change of materials, and the time of the start of the work.

- Work order: functions to manage job order information and to checklist for each task in the work order.

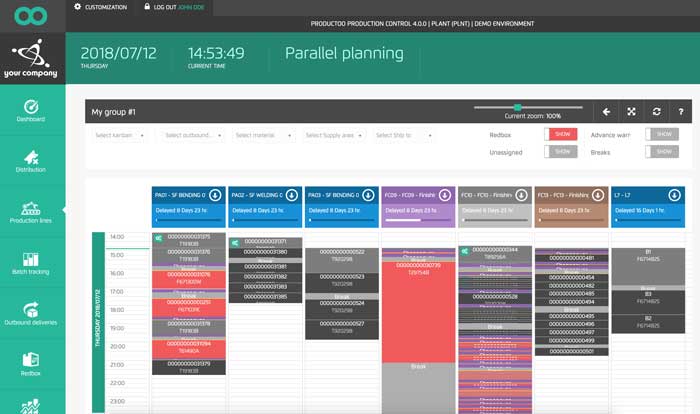

- Order planning: enabling manufacturers to organize and change production schedules and plan the resources needed for production.

- Bill of materials: to help manufacturers make production formulas or to determine the components needed in the manufacture of a product.

- Routing: selecting sequences for products and work orders and managing complete information such as bomb codes, work center, machine ids, labor names, type of duration and much more.

- Designing software

On the additive manufacturing industry, product design software applications are indispensable.

Use 3d – integrated design software and be able to design for any kind of product, steel products, sparepart products, or smaller products.

On design software divided into two.

This type of manufacturing application is computer manufacturing design or cad and computer manufacturing or CAM.

The differences, cad is used to make, modify, analyze, and optimize geometric design.

While CAM is a factory application to optimize existing design and integrate it into a factory tool or machine.

- Inventory management Software

Manufacturing is so subject to inventory such as machines, k3 equipment, partings, and also other small devices that a company must have software that can help control, classify, accommodate and also evaluate the value of inventory.

There are several examples of manufacturing applications on the market that you could use.

Here are some of those owned by a good inventory management system:

- Stock level management: help the inventory manager to set the minimum levels of supplies and post a warning when the supply level is close to the minimum.

- Procurement management: helps manufacturers reorder automatically for certain materials to supply when supplies are scarce.

- Supplier management: store all complete information about suppliers so it makes it easier for producers to find items with the best deals.

- Forecasting: helping manufacturers to know high – demand items and predict future materials to avoid unnecessary purchases.

- Supply chain management software of manufacturing applications

Management of supply chains or supply chain management is a systematic approach to managing the distribution of goods from providers of raw materials, through producers, and finally to the consumer or end user.

Manufacturing companies need simplification, luxury, and supply chain management to accelerate the production process especially business so that companies are no less competitive with volatile competition in 4.0.

Features owned by supply chain management software should be able to predict supply, manage and easier orders, distribution tracking, and return management.

- Customer Relationship Management Software

At present, business processes not only talk to the needs of the customer but understand the customer’s wants or personalized marketing.

This is where the role of CRM software is needed most. Of course there are many examples of CRM manufacturing applications that you could use.

Using CRM software, the manufacturing business can also predict what will be required within the next few months and use techniques such as lean manufacturing and automation to meet customer requests.

Here’s a feature that CRM software must have:

- Customer data management: it makes it easier for manufacturers to manage the complete information their current subscribers and customers have.

- Sales pipeline management: enable sales teams to create and monitor sales stages, track sales status, and analyze opportunities.

- Marketing email: it facilitates the marketing team to create and to project for prospects and customers according to their schedules.

- Sales reports: helping manufacturers gain complete insight into profit and losses in sales, analyzing customers and prospects, finding out sales turnover, and so on.

- Sales management: helping sales managers distribute prospective customers to the right sales force while monitoring their performance.

- Accounting Software Aplikasi Manufaktur

Finance may be the first software invented to meet the financial management and corporate accounting needs.

The list of the full accounting features of the journal and the financial report applications may be able to, in effect, move excel functions intact in managing finance and accounting.

Accounting software with full features for a company should be able to record real-time transactions and cloud-based, create invoices, record cash flow, track unpaid costs, as well as connectivity with Banks.

- Human resource information management software manufacturing applications

The next software the manufacturing company should own is hris software.

Management of human resources will give more focus to business processes.

Hr’s software should also have features as follows:

- Management: manage salaries with various tax elements, leave, overtime money, THR, online salary slips, and deductions in wages. Salaries can also be performed automatically without a late payment or a mispayment on a paycheck.

- Time management: between absences using GPS and mobile, application of special leave, and work from home. The overtime system can also be done in a transparent way.

- Shift trading and application: with this feature you as a human, can easily manage shifts fairly and automatically.

- Management database: configure employee databases to facilitate and accelerate the flow of communication.

Conclusion

As a quick industry, manufacturing has a very hustle need in all its aspects of the production process.

Thus the use of manufacturing programs became a compulsory provision by manufacturing companies to advance and achieve all objectives.

Therefore, it was necessary to understand manufacturing production planning software for upper middle-scale enterprises.