As an industry that has solid operations and has production goals every day.

Of course, manufacturing companies need the best manufacturing erp software as a solution to boosting corporate performance.

The best manufacturing software is software that meets the needs of the company, is easily accessible, solves corporate problems, and possesses pricing packages that suit its budget.

With the help of the hash manufacturing system from hashmicro, you can cut out activities that waste a lot of time and energy by inspecting various manufacturing processes.

It is more obvious that the subject of the following best cloud based manufacturing software.

What’s Manufacture Equipment Software

Web-based manufacturing applications can help simplify the process of producing this software company is an important and high-priority system in your manufacturing business.

Because it is specifically designed to automate complex and repetitive processes in the production of your manufacturing business.

It will also help simplify the production process and enhance the performance of your company.

With the help of these software, you can certainly be helped in manufacturing and strengthening your manufacturing plans.

Manufacturing software from hashmicro can also help manage production, engine maintenance, and can monitor the stock capacity your company has produced through the dashboard of your manufacturing software.

Here is an important feature in manufacturing software that you should know about:

- Manufacturing plan

The feature of manufacturing plan can help your manufacturing business in managing and effectively assist all manufacturing orders.

It will also ensure that you can adjust production by demand, fluctuations of supply chain, and production capacity.

- Work order

The features of this work order will help you in determining production or routing processes automatically.

It can also assist in tracking the length of production, as well as in locating optical crevices as well as potential problems during production in your manufacturing business.

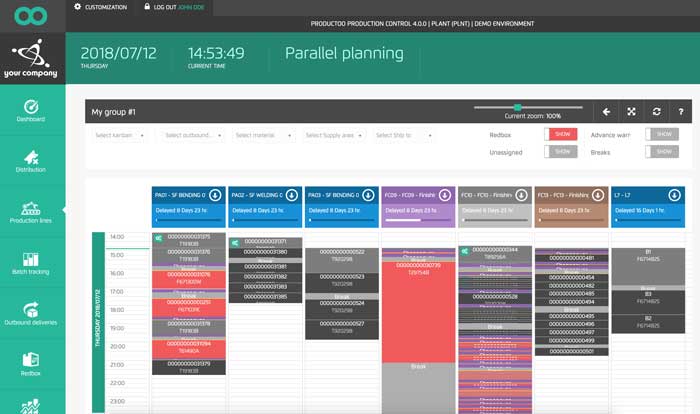

- Schedule management

The third feature is schedule management. Of course, with organized production control management, it can help you to establish an accurate production timeline, to adapt to existing resources, and to minimize both idle and down time in your manufacturing business.

- Bill of management materials

The next feature is bill of materials (bombs), which on bomb features you can be helped in establishing the work in progress (wip) and raw materials needed to produce goods, to calculate automatically, and to distribute them in real time.

That way companies can maximize all the best components that can be technically maximized more easily.

- Routing

The recent feature of routing, this feature can help your manufacturing business in determining production sequences to job commands easily.

This feature, in turn, can manage complete information such as bomb codes, work center, machine id, employee names, type of duration, and so on.

- Inventory software management for manufacturing companies

Web-based manufacturing applications minimize risk delay in inventor-management productivity which is a system that businesses or every manufacturer needs.

It can help your business to ensure the company’s supply of raw materials. In this way companies can minimize the risk of tardiness in the production process.

The following are four features you will get with a good inventory management system:

- Stock management

This feature may help the inventory manager’s performance in managing the minimum levels of supplies and installing and giving warnings as the supply supply is close to the minimum.

Therefore, companies need to maximize all the procedures and maximum access in stock management.

- Procurement management

The next feature is procurement management, which may help manufacturers when rebooking is made automatically for certain materials to be made when stock supplies are scarce.

- Supplier management

The function of advanced management is that it can store all complete information on incentives so that it can make it easier for corporate producers to search and locate them with the best deals.

- Forecasting

Forecasting can make it easier for producers to know high – demand items and predict future production requirements, thus avoiding unnecessary purchase of goods or materials.

- Supply chain management software for manufacturing companies

A web-based manufacturing application can monitor in and out of logistics of comply-chain management or in indonesian-language terms known as supply chain management is a systematic approach to managing distribution of goods from raw materials.

Then through the manufacturer, and it ends on the consumer or the last user.

Though, in resemblance to the previous software, the SCM system focuses on keeping logistical communications in check for the loading and unloading of goods properly monitored.

Certainly in order to facilitate corporate performance, the manufacturing business needs the assistance of supply chain management (SCM) software to simplify the company’s supply chain and accelerate production processes.

The best supply chain management software should certainly have superior features.

Such as being able to track availability of items in a warehouse, make it easier for users to track and fill customer orders, and be able to track the location of the couriers to make sure that all the customer orders can be sent in time.

- Accounting software for manufacturing companies

Web-based manufacturing applications can also minimize current human errorist, accounting software that is crucial and appropriate for any business or company consider its use.

This software makes it possible to track detailed financial transactions and to produce quick and efficient accounting reports.

This accounting system does not fully replace the role of the accounting manager in managing the company’s finances.

However, it makes performance easier for them to work more productively and effectively.

- Hris for manufacturing companies

Finally, the critical software manufacturing companies own is the hris software.

In a manufacturing company, employees are an important asset.

Because, an employee is the figure who will run the production process in your manufacturing company.

Therefore, a company should be able to ensure the welfare and take into account the compulsory rights of its employees.

Therefore, companies should consider using the best HRM software already integrated.

The following are four main benefits from the hris system for your manufacturing business:

- Employee databases that you can automatically update from hris online, can then facilitate the process of mutations, promotion and acceptance of new employees.

- Google calendar integration with the HRM application hashmicro would make for interviews with employee candidates easier.

- Cash advance, leave, and reimbursements can be traced and processed instantaneously through this bid software.

Conclusion

Simply put, web-based manufacturing applications can help your manufacturing companies optimize the efficiency and productivity of the company’s production process.

So if you still find it difficult to determine which manufacturing software is appropriate for your company, then best cloud based manufacturing software would be the best choice you could consider.